View the original article here.

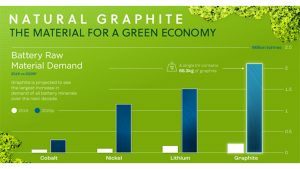

In pursuing a sustainable and eco-friendly future, the demand for natural graphite has soared, especially after more and more countries have started working towards the electrical green economy revolution.

Reflex Advanced Materials (CSE: RFLX) (OTCQB: RFLXF), a forward-thinking exploration company, has taken the lead in this valuable mineral by setting its sights on Montana’s past-producing vein graphite mine.

This move not only marks a pivotal step towards securing a domestic supply of graphite, but also plays a crucial role in bolstering national security, reducing dependence on foreign sources, and unleashing the potential of high-tech applications.

Synthetic versus natural: Unveiling the power of natural graphite

The power of natural graphite over its synthetic counterpart has become increasingly evident, bolstering the argument for a secure domestic supply within the US.

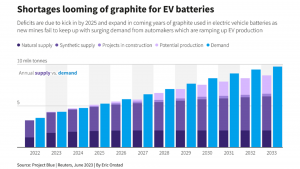

While the current battery industry leans towards synthetic graphite, which holds the lion’s share of the anode market, a shift is occurring. Businesses are moving towards natural graphite because of cost advantages and environmental benefits.

Superior conductivity

Natural graphite’s thermal and electrical conductivity outmatch synthetic graphite, making it the preferred choice in applications that require efficient energy transfer. For instance, the U.S. Geological Survey has identified natural graphite as one of the 35 critical minerals due to its unique properties, making it suitable for high-value applications like nuclear reactors, fuel cells, and graphene production.

Thermal resistance

Natural graphite maintains stability at high temperatures, a feature synthetic graphite lacks. This makes natural graphite ideal for applications that involve high heat.

Eco-friendliness

Natural graphite has a smaller carbon footprint than synthetic graphite, making it more environmentally friendly. The mining of natural graphite produces the only significant emissions, while synthetic graphite production releases over 4.9kg CO2 per kilogram, which is three times more CO2 than 1kg of natural graphite.

With these unique properties, natural graphite holds a clear edge over synthetic graphite. This advantage underscores the importance of Reflex’s efforts in securing a consistent domestic supply of this crucial mineral within the US.

The distinguishing brilliance of vein graphite

Natural graphite consists predominantly of two primary forms: flake graphite and vein graphite. Each has its distinguishing features, yet vein graphite stands out for its superior qualities, especially concerning its application in innovative and high-tech industries.

Flake graphite, the more common form, is predominantly used in refractories, foundries, and batteries. It is formed through the metamorphism of organic-rich sediments, resulting in a layered structure that is soft and flexible.

However, it requires extensive processing to remove impurities and achieve the desired particle size and shape, which can lead to higher costs and environmental impacts. Despite these drawbacks, it still carries significant market value due to its abundance and the wide range of industrial applications it can serve.

On the other hand, vein graphite, though rare, is highly valued for its unique properties that make it ideal for high-tech applications. This type of graphite is formed by the crystallisation of carbon-rich fluids in metamorphic rocks. It is known for its high carbon content (up to 99%), compared to flake graphite’s typical 85-95%. The high purity of vein graphite reduces the need for processing, making it cost effective and more environmentally friendly.

Distinguishing features of vein graphite include:

- Crystalline structure: Vein graphite has a unique crystalline structure, giving it a higher thermal

conductivity than flake graphite. This makes it the preferred choice in electronics to energy storage industries; - High purity: With a carbon content of up to 99%, vein graphite’s high purity makes it ideal

for applications that require consistent quality and performance. Its exceptional purity is utilised in high-value applications such as nuclear reactors and fuel cells; - Eco-friendliness: Compared to flake graphite, vein graphite requires less processing. This, in turn, leads to less waste production, thus making vein graphite a more environmentally-friendly option; and

- Market value: Due to its rarity, purity, and unique properties, vein graphite commands a higher price per tonne than flake graphite, making it a higher-value product.

In terms of its use in advanced technologies, vein graphite’s unique crystalline structure makes it more favourable for high-tech applications.

For instance, the production of graphene, a cutting-edge material with vast potential in electronics, often employs vein graphite due to its high purity. Furthermore, its high thermal conductivity makes it suitable for nuclear reactors and fuel cells.

Given the importance of graphite, particularly vein graphite, in high-tech applications, securing a domestic material supply is crucial for the US.

As we progress towards a future powered by renewable energy and electric vehicles, the demand for high-quality vein graphite is expected to increase further, emphasising the need for a reliable and sustainable domestic source.

With the US currently dependent on imports for its graphite supply, establishing a robust domestic supply chain should be a top priority.

Securing a domestic supply with Reflex Advanced Materials

Reflex Advanced Materials Corp (CSE: RFLX) (OTCQB: RFLXF) has strategically moved toward safeguarding America’s domestic graphite supply by acquiring the rights to the Ruby Graphite Project in southwest Montana.

The Ruby Graphite Project is a past-producing mine that potentially holds vast amounts of natural vein graphite – a critical resource for various high-tech applications. This acquisition signifies a pivotal step in Reflex’s mission to reduce US dependence on foreign imports for graphite, particularly from China which currently holds a strong position in the global graphite market.

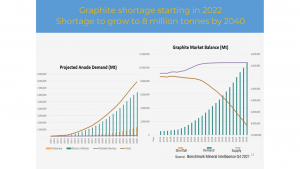

Growth in graphite demand

The demand for graphite, a key component in lithium-ion batteries, is projected to increase significantly with a Compound Annual Growth Rate of 8.01% from 2023 to 2028. As the electric vehicle space continues to expand, the need for graphite, particularly in the battery segment, will also surge, evident from the 80% increase in vehicle battery demand in 2022 in the US alone.

China’s dominance in graphite supply

Currently, China dominates the graphite market, accounting for over 60% of global production. Almost all downstream graphite processing involves at least one stage in China. The US can reduce dependence on China by developing a domestic source, as Reflex does at the Ruby Graphite Project, thereby securing supply chain stability.

Supporting US decarbonisation efforts

Graphite is essential for electric vehicles and other high-tech applications crucial to the US’ decarbonisation and vehicle electrification ambitions. Therefore, securing a domestic supply chain for this critical mineral is a requisite for these national goals.

Facing this level of demand, it is clear that decisive action is required to secure graphite supply for the future. Reflex Advanced Materials Corp is taking a giant leap towards building a robust domestic graphite supply chain by securing access to the Ruby Graphite Project.

This step is pivotal for the US to maintain its position in the electric vehicle market and reduce its dependence on foreign sources, ensuring a sustainable and secure future for its ambitious decarbonisation and vehicle electrification plans.

Empowering the electrical green economy revolution

The surging popularity of electric cars, hybrid cars, laptops, and smartphones, which all heavily rely on lithium-ion batteries, is causing the demand for graphite to skyrocket. Further fuelling the demand is the increasing adoption of high-technology applications like carbon-graphite composites and flexible graphite products.

The US, which imported 53,000 tons of natural graphite in 2021, with 33% of it coming from China, is starkly dependent on foreign sources for its graphite supply.

However, this dependence is poised to change with the US government allocating $750m under the Title III fund to support domestic production and supply chain development of critical minerals like graphite. President Joe Biden has also invoked the Defense Production Act to spur US production of minerals for electric vehicle batteries and reduce reliance on foreign supply.

One of the promising domestic graphite projects in the US is the Ruby Graphite Project in southwest Montana, managed by Reflex Advanced Materials Corp. This deposit aligns perfectly with the vision of a greener and more electrified future, and the U.S Department of Energy’s allocation of funds to develop the country’s battery supply chain further underscores this commitment.

The urgency to establish a secure supply of domestic graphite is about meeting the rising demand and empowering the US to lead the global green economy revolution. Thus, graphite stands at the heart of the sustainable future we strive to build.

View the original article here.